ASTM A335 is a seamless ferrous alloy steel pipe used in the high temperature service and boiler industries. Ordinary second level P5, P9, P11, P22, P91.

ASTM A335 pipe, also known as ASME S/A335 chromium solution pipe, is a seamless pipe used in high temperature environments of 540 - 750°C. It covers nominal walls and minimum wall thickness tubes with alloy material. Pipes under this specification shall be suitable for bends, flanges and all other similar treatments and formations. Although this should be beneficial for fusion welding. The material can also be used to produce pipe fittings such as elbows, tees, reducers and flanges.

P5, P9, P11, P22 and P91 pipes are referenced in ASTM A234 WP5, WP9, WP11, WP22 WP91 for pipe fitting materials, among which ASTM A182 F5, F9, F11 and other flange materials have similar chemical composition and mechanical properties.

Our range of A335 duct supplies

Standards and Grades: ASTM A335 Grades P5, P9, P11, P22, P91

Material type: chromium alloy steel pipe

Fabrication Type: Seamless Pipe Hot Roll or Cold Water

Sizes: 1/2'' to 24'

Wall thickness: SCH 40, SCH STD, SCH 80, SCH XS, SCH 160

Length: 6 meters, 12 meters or customized.

ASTM A335 piping features

The presence of chromium and molybdenum is high in A335 tubes. While molybdenum increases overall strength, resistance, elasticity, durability and overall quality, Morley ensures the material is more resistant to softening, limiting grain growth and reducing the chance of brittleness. It is the single additive responsible for the increased resistance to high temperatures and also increases the corrosion resistance of steel.

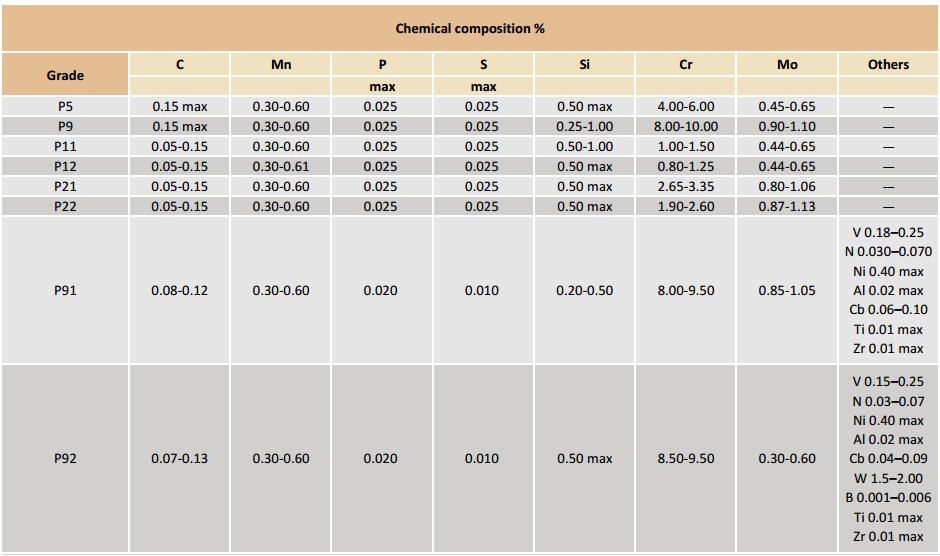

A335 Pipe Chemical Composition

Mechanical Properties

|

Grade |

Yield Strength Mpa [ksi] |

Tensile Strength Mpa [ksi] |

Elongation % |

Hardness Brinell |

|---|---|---|---|---|

|

P5 |

205 [30] |

415 [60] |

30 |

207 max |

|

P9 |

205 [30] |

415 [60] |

30 |

- |

|

P11 |

205 [30] |

415 [60] |

20 |

- |

|

P12 |

205 [30] |

415 [60] |

30 |

174 max |

|

P22 |

205 [30] |

415 [60] |

30 |

- |

|

P91 (1,2) |

415 [60] |

585 [85] |

20 |

a |

a: P91 type 1 and 2 hardness range from 190 to 250 [HBW] or 196 to 265 [HV] or 91 HRBW to 25 HRC.

Dimension Tolerances

Tolerance in wall thickness:

|

NPS [DN] Designator |

Tolerance % on Wall Thickness |

|

|---|---|---|

|

Over (+) |

Under (-) |

|

|

1/8 to 2 1/2 [6 to 65] for all t/D ratios |

20.0 |

12.5 |

|

Above 2 1/2'' [65], t/D ≤ 5% |

22.5 |

12.5 |

|

Above 2 1/2 [65], t/D > 5% |

15.0 |

12.5 |

|

t = Wall Thickness; D = Outer Diameter |

||

Permissible variations for Outer Diameter:

|

NPS [DN] Designator |

Over (+) |

Under (-) |

||

|---|---|---|---|---|

|

in. |

mm |

in. |

mm |

|

|

1/8 to 1 1/2 [6 to 40] |

1/16 (0.015) |

0.40 |

1/16 (0.015) |

0.40 |

|

Over 1 1/2 to 4 [40 to 100] |

1/32 (0.031) |

0.79 |

1/32 (0.031) |

0.79 |

|

Over 4 to 8 [100 to 200] |

1/16 (0.062) |

1.59 |

1/32 (0.031) |

0.79 |

|

Over 8 to 12 [200 to 300] |

3/32 (0.093) |

2.38 |

1/32 (0.031) |

0.79 |

|

Over 12 [300] |

+/- 1% of the specified outside diameter |

|||